Production: minimise our carbon footprint

Environmentally speaking, production is an important step in the product's lifecycle, and our manufacturing processes have changed over the years as we focus on reducing the carbon footprint at our different sites.

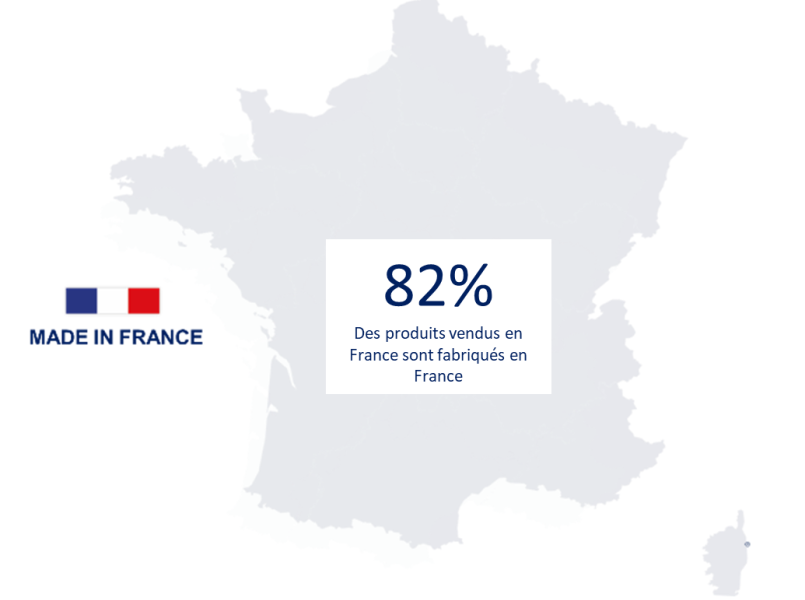

Our strategy involves developing local production capacities with the aim of cutting down on transport, reining in the amount of energy used at our plants and obtaining certification to improve their continuous operation.

Gerflor, the best solution for your floors

The Gerflor Group designs, manufactures and markets an innovative, decorative, eco-friendly and end-to-end range of flexible floor covering solutions, including snap-together and glue-down vinyl tiles, and vinyl floor rolls, from installation to finishing, to enhance your home interior, such as floors for master bedrooms, floors for children's bedrooms, floors for kitchens and floors for bathrooms.

Our product range meets the specific needs of each market application. Always aiming for greater inspiration, well-being, safety, performance and return on investment - Architecture, Decoration, Sport, Technospecific.